Marking perfectly at Fenner

- steve8125

- Nov 7, 2025

- 2 min read

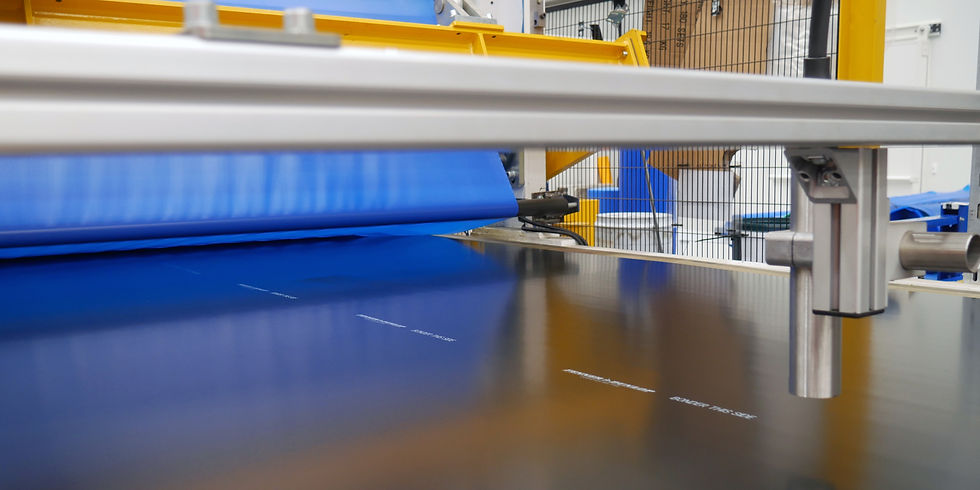

Fenner Conveyors, a member of the global Michelin Group, is a leader in the manufacturing and supply of conveyors for mining and industrial applications. The company needed a solution to correctly identify the bonding layer on its rubber products – without disrupting the manufacturing process. Leibinger’s IQJet printer took on the challenge, and the outstanding results speak for themselves.

As a Michelin Group company, Fenner is committed to an all sustainable approach. Its many trusted brands are recognised globally for providing innovative products and services that solve complex challenges and support sustainable growth. It has been manufacturing in Australia since 1890. At its facility in Melbourne, the company produces uncured rubber for splice kits and conveyor products and has processed over 200,000 kilos of rubber compound.

Rubber is an difficult substance to print on and reliable ink adhesion to the rubber surface had to be guaranteed. It was very important to select ink that is ‘fit for purpose’. The IQJet helped Fenner meet the challenge by clearly identifying which side is the bonder, while introducing effective branding onto the product. ‘Leibinger’s range of ink is quite exceptional. We tested a multitude of inks on different rubber products. The support through the entire process was amazing. We sent our material samples to Germany and had the printing samples results back within two weeks. We were then able to quickly decide on implementing the IQJet with the perfectly matched ink,’ explained Jeremy Van Kaathoven, extrusion manager at Fenner Conveyors. ‘In addition, Leibinger’s five year maintenance free operation means less cleaning, less downtime – and greater overall productivity.’

The printer is an ideal solution for coding and marking in many different industries, offering innovative plug and print performance for high print quality and availability without cleaning. This technology revolutionises the continuous inkjet (CIJ) experience, providing five years of hassle free operation without scheduled maintenance. With its exceptional performance, cost savings of up to 30%, and focus on sustainability, the IQJet helps businesses reduce their ecological footprint while greatly increasing productivity.

The nozzle sealing technology is truly innovative. While conventional printers have to be cleaned after production breaks, the ink remains in a closed circuit in the IQJet. This prevents the nozzle from clogging and dramatically reduces the need for solvents. Production lines remain clean, maintenance is reduced, downtime is kept to a minimum and the printer is always ready for use. As the most economical overall concept, the printer delivers low cost of ownership.

Even in everyday use, it demonstrates its strengths, as Ashley Burge, leading hand at Fenner Conveyors, explained: ‘As an operator, I find the printer very easy to use. Because of the printer’s stop and start feature, it idles whenever not in use, greatly reducing costs and energy use. An innovative recovery technology returns evaporated solvent to the system – saving up to 50% of the solvent used.’

Comments